Ecm Vacuum Furnaces

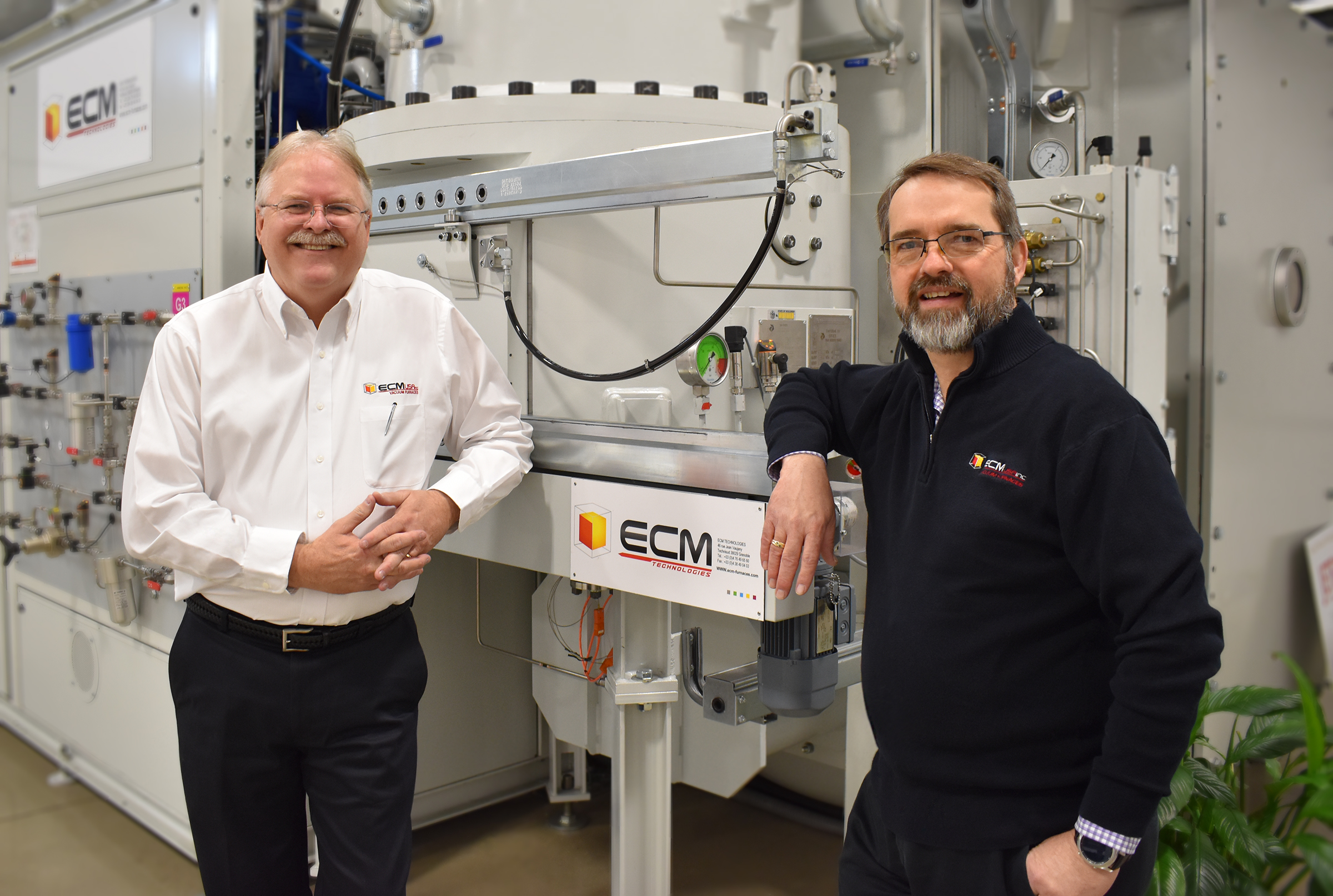

Men and women supporting ecm technologies are accomplished and expert entrepreneurs.

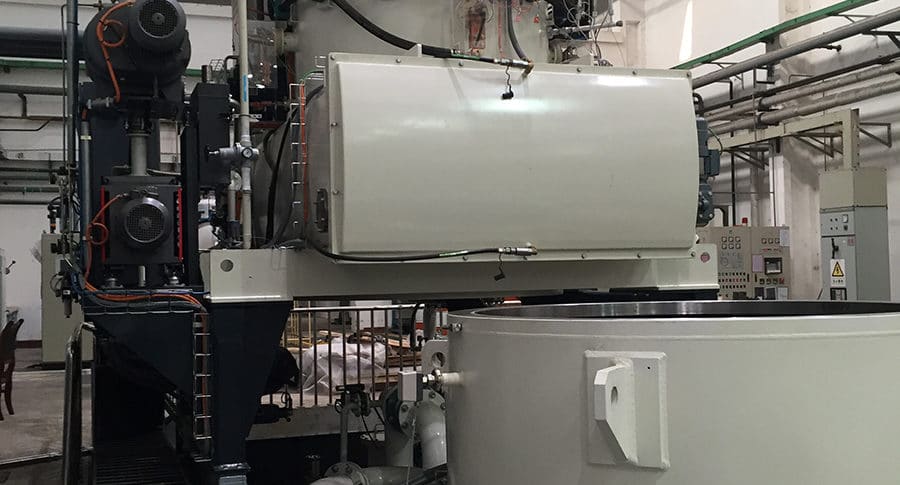

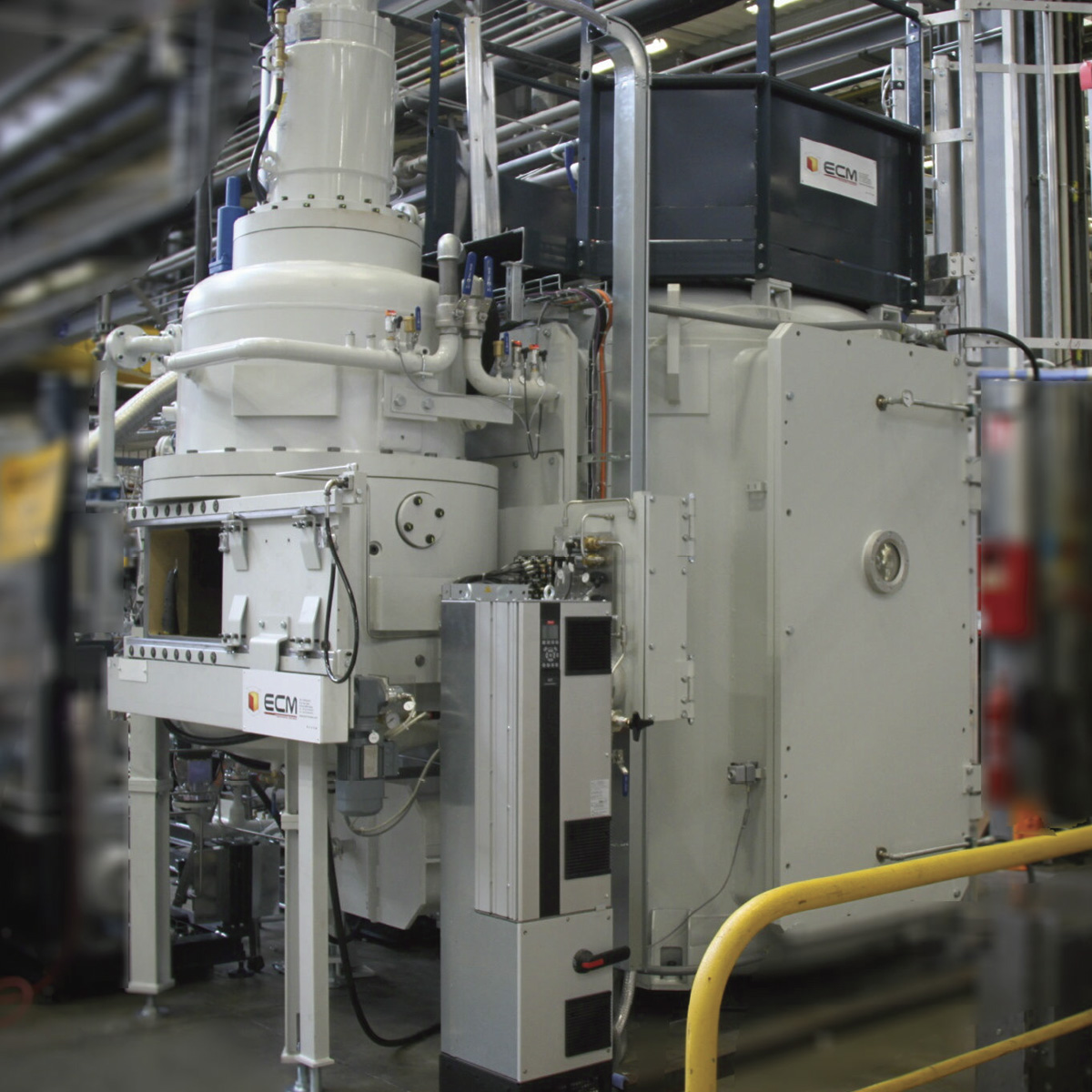

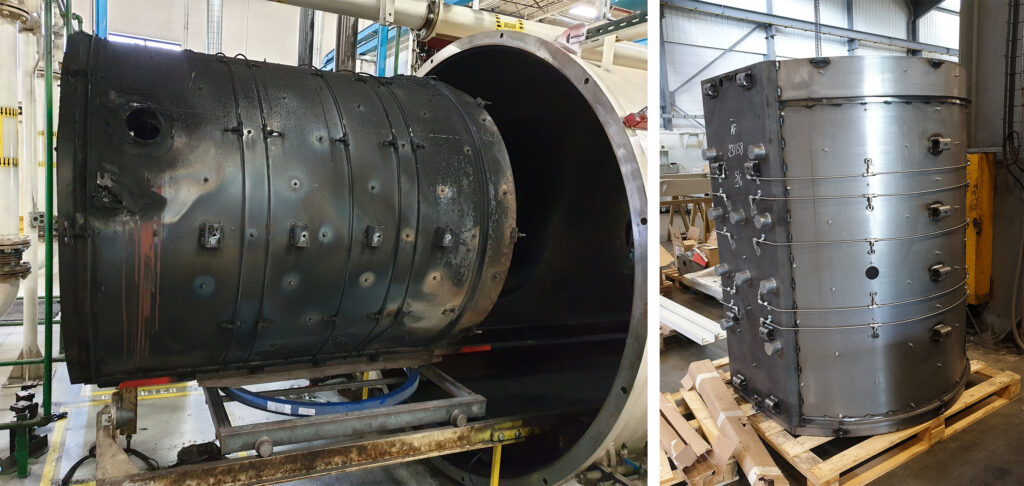

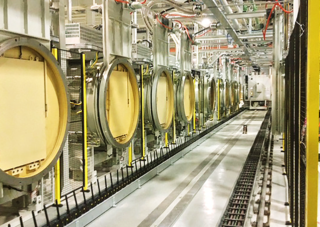

Ecm vacuum furnaces. Ecm technologies has been manufacturing vacuum furnaces since 1964. The new ecm vacuum carburising furnace with oil quench capabilities will help meet growing demand from makers of high end critical parts within the automotive aerospace and tooling industries. Today more than 1 500 furnaces are installed throughout the world for an extended range of applications. Info ecmtech fr 46 rue vaujany technisud 38029 grenoble.

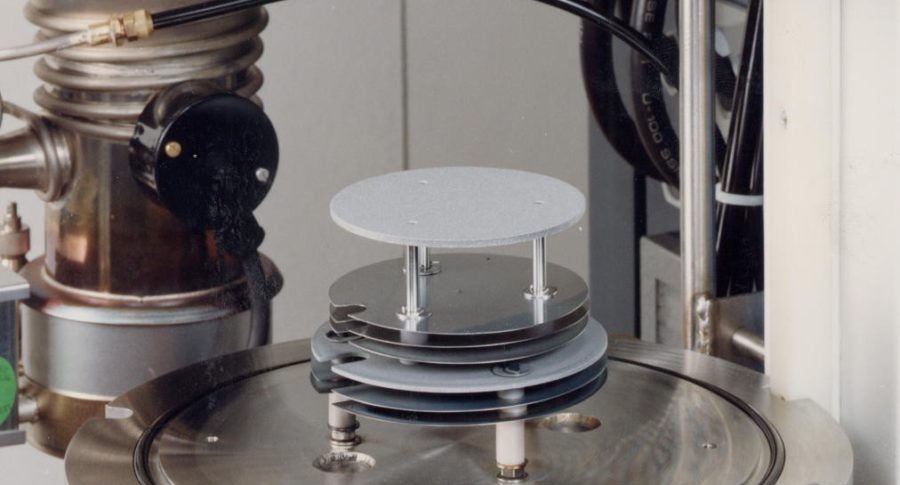

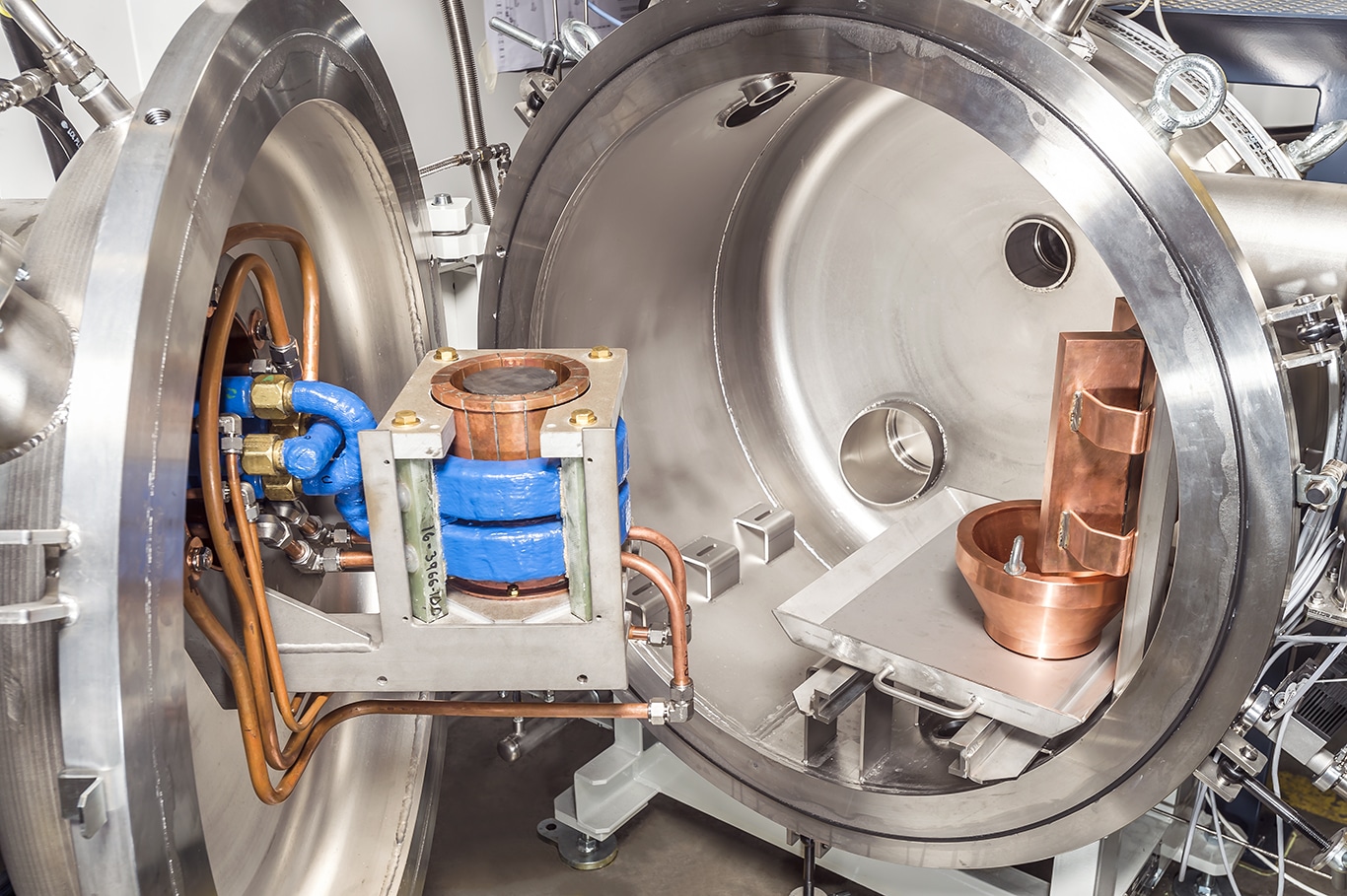

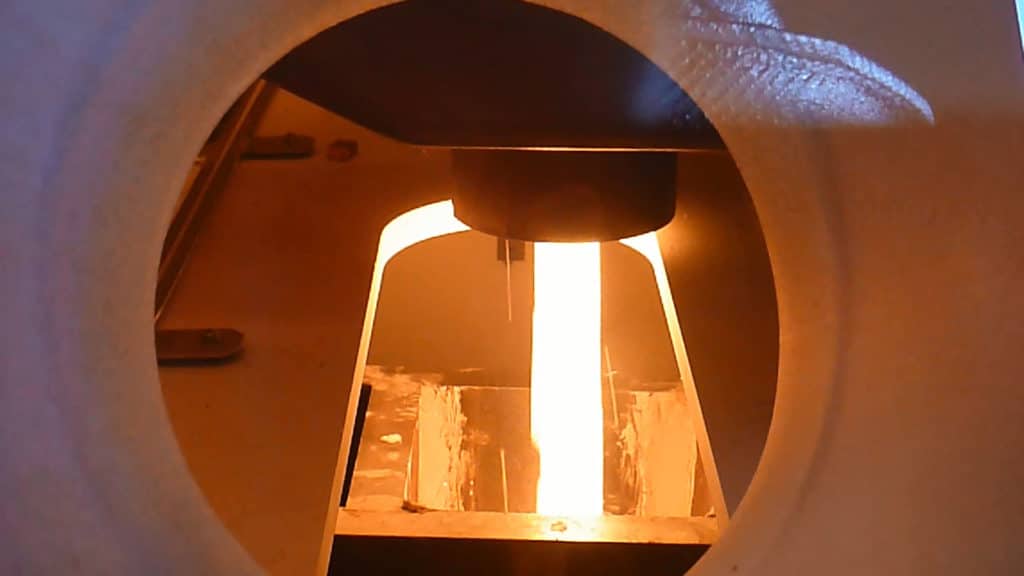

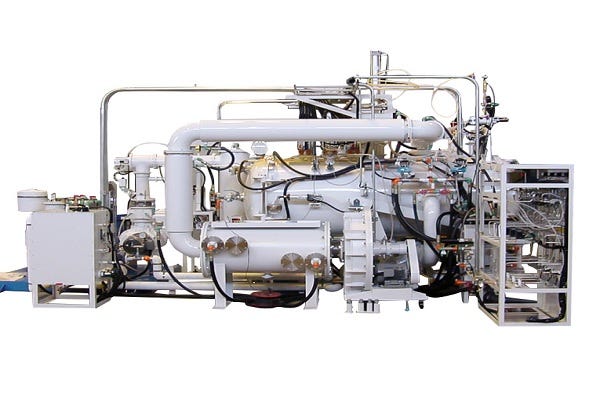

Induction melting furnaces offer the possibility to carry out complex processes at high temperatures up tp 3000 c with a rapid rise in temperature 30. As a leading global industrial vacuum furnace manufacturer ecm s mission is to design and manufacture high quality low pressure vacuum carburizing carbonitriding brazing sintering and induction melting furnaces and automated systems in north central and south america click here for more applications or contact us our vacuum furnace systems benefit from more than 50 years of engineering. As an industrial vacuum furnace manufacturer ecm usa s mission is to provide you high quality low pressure vacuum carburizing and vacuum carbonitriding furnaces services and spare parts for ecm technologies products in north central and south america. Contact our head office or one of our subsidiaries.

Ecm is a reference for main contractors with its vacuum carburizing furnaces and its icbp installations. The 20 bar dual chamber furnace has a workload size of 40 l x 24 w x 28 h 1 000 x 600 x 715 mm and a load capacity of 1 500 lbs. Our vacuum furnace systems are built using experienced engineering advanced manufacturing and installation. The world leader for lpc furnaces.

Ecm technologies acquired skills and know how in the manufacturing of vacuum furnaces for high tech applications for more than 50 years and developed its robotics skills for all kinds of applications. Ecm technologies mastery of high temperatures vacuum and controlled atmospheres has allowed it to propose turnkey induction solutions for various applications including vacuum melting. With more than 90 years of dedication to improving thermal applications for many industries. 33 0 4 76 49 65 60 mail.

Low pressure vacuum carburizing annealing ageing magnetic vacuum brazing gas quenching oil quenching sintering post additive manufacturing.