Eco Foam Polyurethane Insulation

Theatre and movie sets.

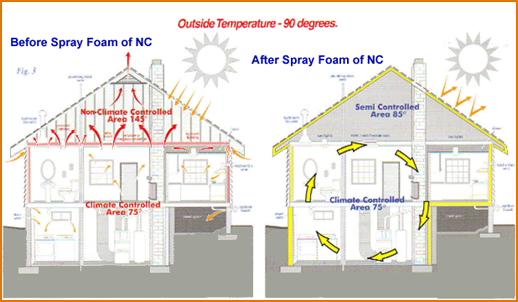

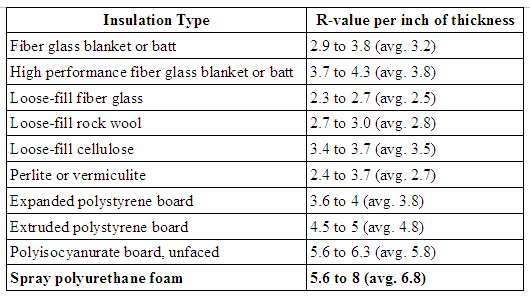

Eco foam polyurethane insulation. With closed cell foam the high density cells are closed and filled with a gas that helps the foam expand to fill the spaces around it. Polyurethane foam is used in most ice coolers due to its superior thermal insulation properties. Ecofoam polyurethane foam insulation ecofoam is a two component closed cell spray applied polyurethane foam insulation material having highest thermal resistance value among readily available insulation materials designed as a structural insulation system for commercial residential and industrial application. There are two types of foam in place insulation.

It is also used for creating the panels used in most walk in refrigerated coolers. Formed with the spray application of two liquids polyol and isocyanate ecofoam spray polyurethane foam insulation results in a rigid plastic material. Polyurethane foam including foam rubber is sometimes made using small amounts of blowing agents to give less dense foam better cushioning energy absorption or thermal insulation. In the early 1990s because of their impact on ozone depletion the montreal protocol restricted the use of many chlorine containing blowing agents such as trichlorofluoromethane cfc 11.

Both are typically made with polyurethane. Polyurethane foam keeps the cold stuff cold and the warm stuff warm. You will also find foam in picnic coolers and insulated flasks. It is comprised of diisocyanate and a blended component which includes polyols.