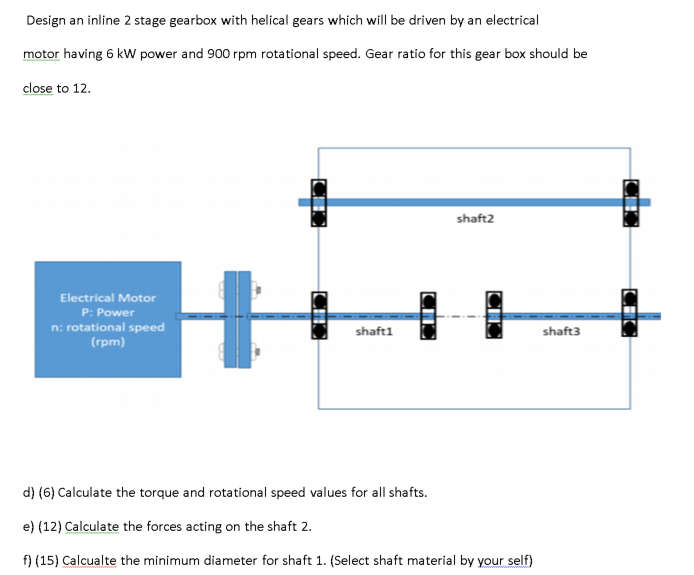

Electric Motor Gearbox Rpm Calculator

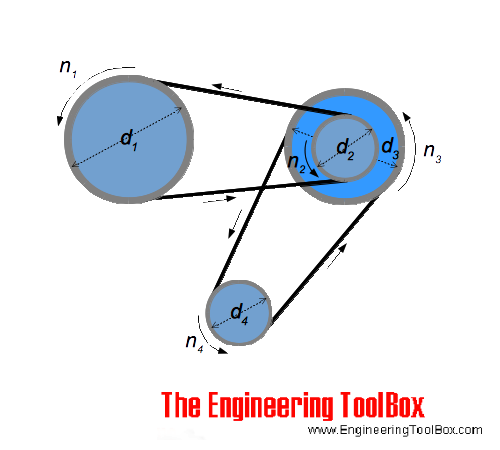

Enter any 3 known values to calculate the 4th if you know any 3 values pulley sizes or rpm and need to calculate the 4th enter the 3 known values and hit calculate to find the missing value.

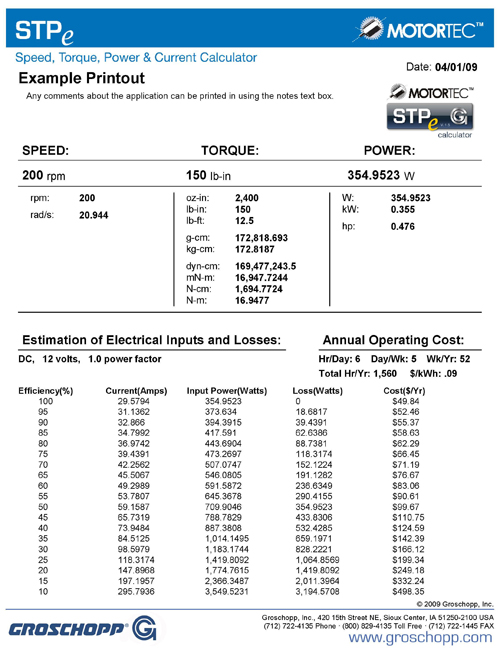

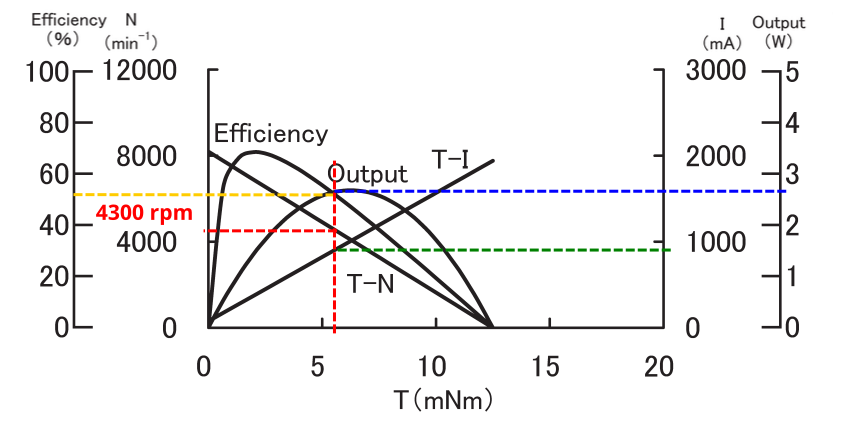

Electric motor gearbox rpm calculator. Rla running load amps current drawn during normal operation of electric motor. Standard motors have shafts directly attached to the motor windings with shaft output speeds commonly between 1800 3000 rpm. At no load you have maximum speed and zero torque. The torque delivered from an electrical motor producing 0 75 kw 750 w at speed 2000 rpm can be calculated as.

We want to see your websites and blogs. In the calculator above fla is rla 25. In order to calculate the gear ratio of the two meshed gears we need to know either. Example torque from an electrical motor.

Motor torque changes with the speed. Output rpm 2000 3 5. Win 100 towards teaching supplies. Check the circle next to the item you are solving for and enter the remain three items in the spaces provided.

1750 rpm 1000 rpm 3 5 inches d 2 d 2 6 125 inches. Fla full load amps amount of current drawn when full load torque and horsepower is reached for the motor fla is usually determined in laboratory tests note. We have now completely verified that our rs 550 motor and 26 1 gearbox will achieve or exceed our original goals. Scientific calculator simple calculator.

1 hp 0 745 kw. Rounded to the nearest 10 000th 100 promotion. If you have any problems with the pulley calculator please email us. Calculating the rpm resulting from a motor and speed reducer assembly requires only basic mathematical knowledge.

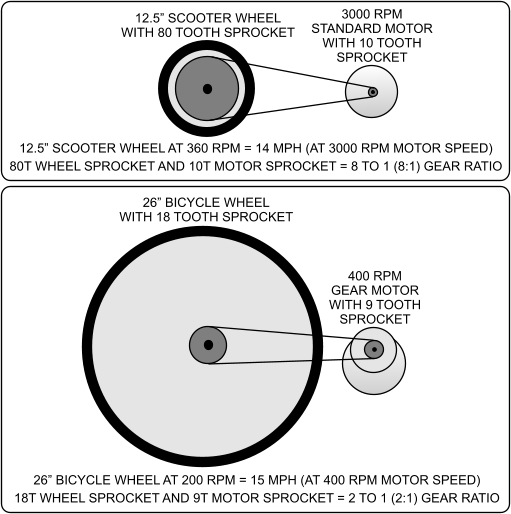

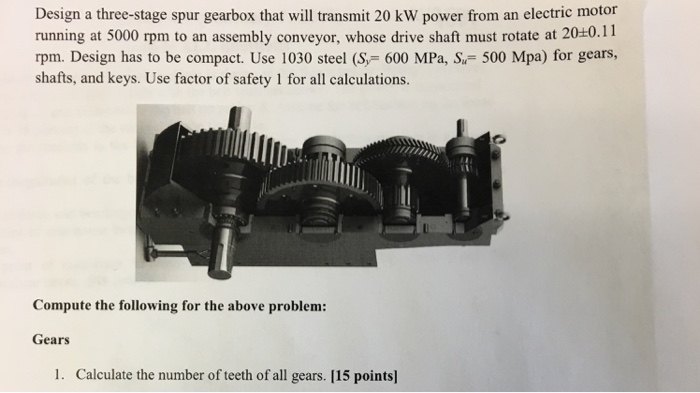

Standard motors and gear motors. How do we calculate the gear ratio. For example if your small pulley is 80mm diameter and spins at 1000 rpm and you need to find the second pulley size to spin it at 400 rpm enter pulley1 80 pulley 1 rpm 1000 pulley 2 rpm 400 and. In our example input electrical power of the motor is 0 22 a x 6 v 1 32 w output mechanical power is 1000 rpm x 2 x 3 14 x 0 00126 n m 60 0 132 w.

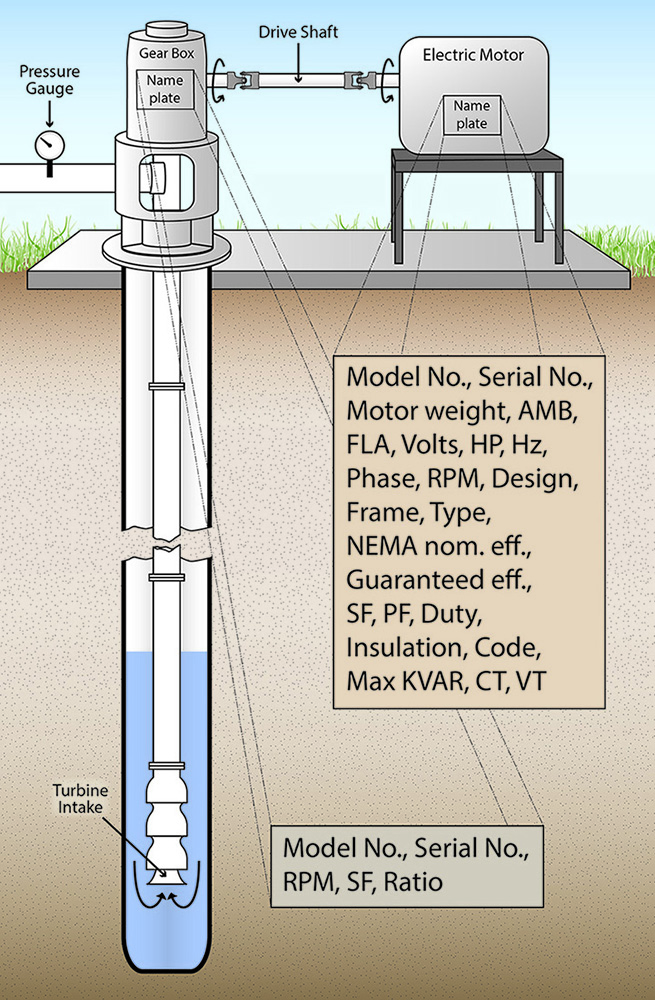

Related mobile apps from the engineering toolbox. Finally now that we have verified that our gear ratio satisfies our requirement we can calculate how long it should take for the motor to raise the elevator. Gear motors have gear reduction transmissions built into them with shaft output speeds commonly between 400 550 rpm. There are two types of electric motors.

The torque delivered from an electrical motor producing 100 hp at speed 1000 rpm can be calculated as. Pulley and speed calculator. T 750 w 9 549 2000 rpm 3 6 nm example torque from an electrical motor. Motors run at a specific revolutions per minute rpm and a speed reducer is needed if you want to keep that motor but have a lower rpm.

Below is a small calculator that will solve the ratio for you. Your source of power is let say an electric motor.