Elevated Water Tank Construction Procedure

In the other hand the underground tanks are rested on the foundation.

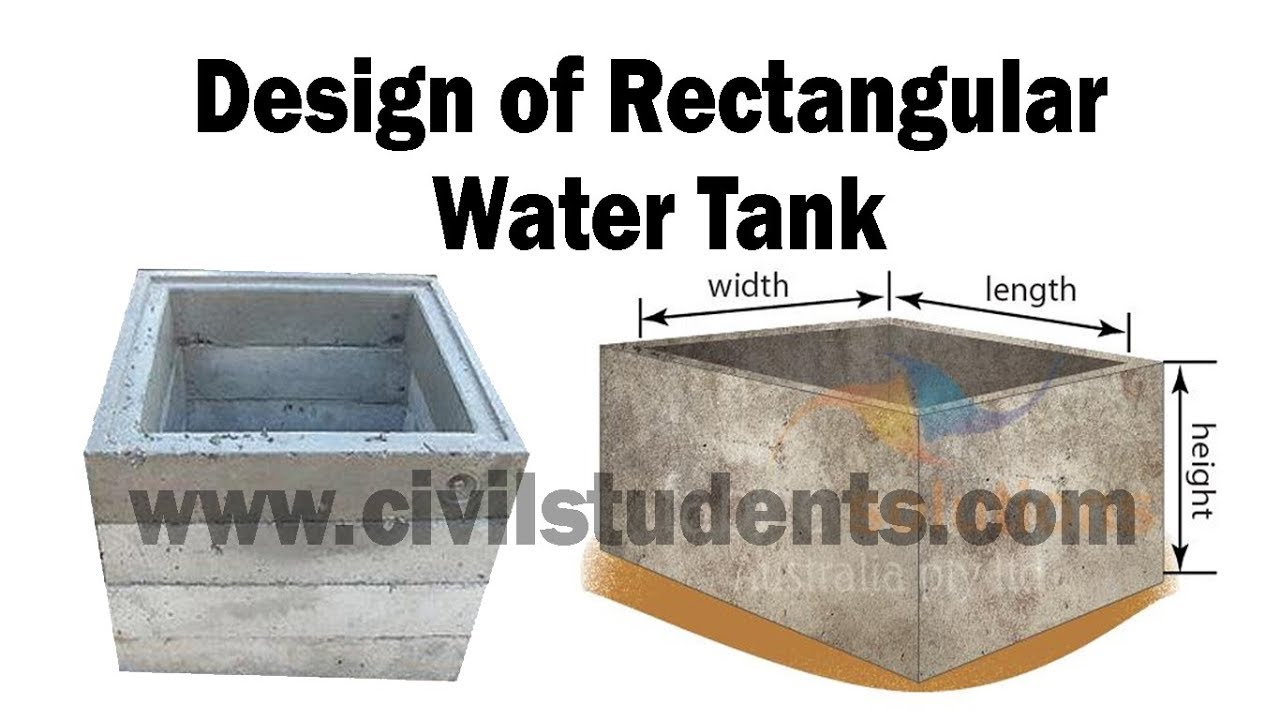

Elevated water tank construction procedure. The construction of the tank shall be hot dipped galvanized steel. Ensure all major components of the tank are complete and available as illustrated on water tank cutout list attached in the material submittal. The steel calculated in step 3 is for 1m height from the bottom of the water tank. In recent years elevated tanks supported by a single pedestal have been constructed where aesthetic considerations are an important part of the design process.

The pressure of water decreases at the top. Reduction in hoop steel. Ht 1000t m 1 ast x σct. Finally you ll need to check the weather forecast and perform a thorough risk assessment.

The landmark spheroid elevated tank construction process involves the shop fabrication of most structural modules and the completion of major on site tasks at ground level to improve cycle time and control quality and safety. Thickness of the wall of water tank. Distribution steel vertically. This needs to have a low density and low slump concrete.

A standpipe is a tall cylindrical tank. Identify all the panels using the parts list. Water tank construction can vary from company to company but here at versatile tanks we follow a specific guide. Hence steel can be reduced by keeping the same thickness of wall.

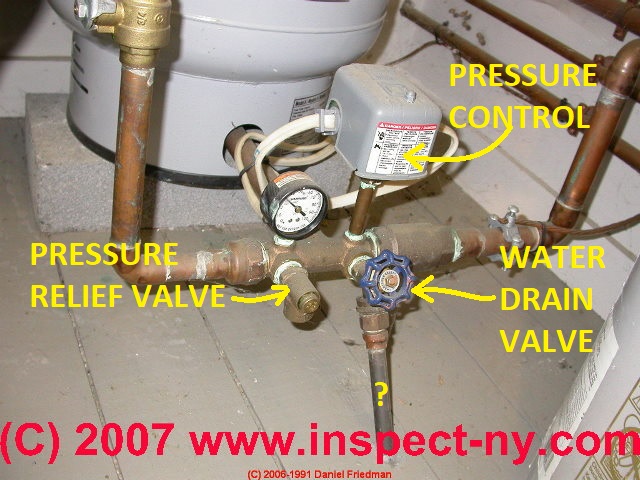

The tanks can be made of reinforced concrete or even of steel. The contractor shall connect to the existing 110mm plastic water main. This is in response to a letter you submitted to the occupational safety and health administration osha via email on july 7 2016 regarding construction work in water storage tanks and osha requirements for confined spaces in construction. A closed and lockable manhole on the top shall be 1 meter by 1 meter to allow access for maintenance.

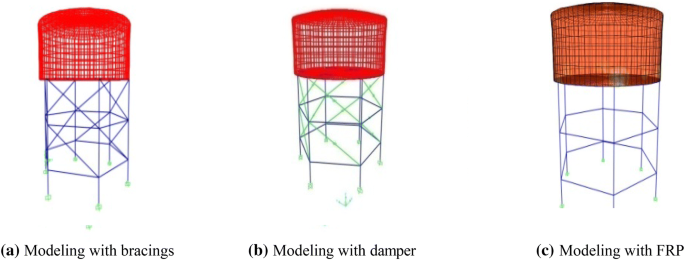

Proposalof water tank design and construction using ferrocement for health center in afar region acknowledgements. Chris lovelace the lovelace group 5805 state bridge road suite g 444 duluth georgia 30097. In this article design requirements of reinforced concrete water tanks are discussed. The most common types of elevated storage are elevated steel tanks and standpipes.

The manhole lid shall provide a tight seal to prevent entry of contaminates. The next step in the process is to order a low slump ballast mix for installation.